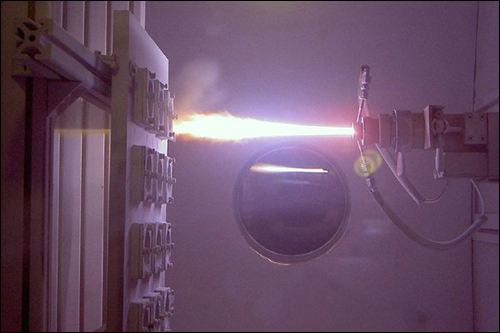

With the continuous development of science and technology, there are more and more types of surface modification technologies, such as surface coating method, ion implantation method and ion extraction method. These methods have significant effects in improving the surface hardness, fracture toughness and bending strength of ceramic materials, reducing friction coefficient, improving wear resistance, chemical properties, high temperature oxidation resistance and mechanical properties. Plasma spraying is a new type of plasma spraying method developed for the shortage of conventional atmospheric plasma spraying. The principle is: the main gas and the secondary gas are input from the back of the spray gun, the flow of the main gas passing between the tungsten electrode and the primary nozzle is small, and the secondary gas of large flow passes through the secondary nozzle through the action of the gas swirl ring ejection. The coating processed by plasma spraying has the following characteristics: the coating of high melting point material is uniform, the coating is dense and hard, the void ratio is small, and the ceramic coating of high melting point material has high bonding strength.

Plasma spraying is a new type of multi-purpose precision spraying method that has been vigorously developed after flame spraying. It has: ① ultra-high temperature characteristics, which is convenient for spraying of high melting point materials. ②The speed of spraying particles is high, the coating is dense, and the bonding strength is high. ③Since inert gas is used as working gas, the sprayed material is not easy to be oxidized.

Plasma spraying is performed using plasma arc. Ion arc is a compression arc. Compared with free arc, its arc column is thin, the current density is large, and the gas ionization degree is high.

There are three types of plasma arcs according to the connection method:

① Non-transferred arc: refers to the plasma arc generated between the cathode and the nozzle. In this case, the positive electrode is connected to the nozzle, the workpiece is not charged, and an arc is generated between the cathode and the inner wall of the nozzle. The working gas is heated by the arc between the cathode and the nozzle, causing all or part of the ionization, and then formed by the nozzle. Plasma flame (or plasma jet).

Plasma spray processing is using this type of plasma arc.

② Transfer arc: The arc is transferred from the spray gun to the plasma arc on the processed parts. In this case, the nozzle is not connected to the power supply, the workpiece is connected to the positive electrode, the arc flies between the cathode and anode (workpiece) of the spray gun, the working gas is fed around the arc, and then sprayed from the nozzle.

Plasma cutting, plasma arc welding, plasma arc smelting use this type of plasma arc.

③Joint arc: Non-transfer arc ignites the transfer arc and heats the metal powder. The transfer arc heats the workpiece to produce a molten pool on the surface. In this case, the nozzle and the workpiece are connected to the positive electrode.