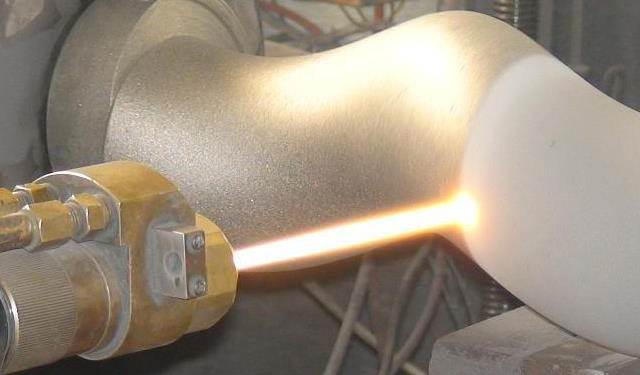

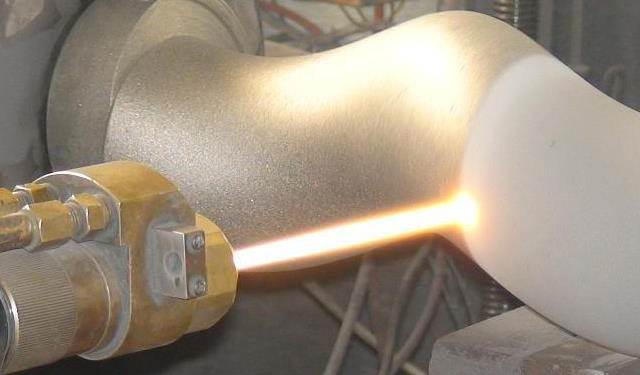

Atmospheric plasma spraying is a common process for depositing ceramic coatings to prevent wear and corrosion. Raw materials include, for example, alumina, titania, and chromia. Plasma sprayed chromium oxide coatings are widely used in anilox rolls, pump seals and wear rings due to their good surface quality, high hardness and wear resistance.

However, chromium oxide has a high melting point, low thermal conductivity, and is easy to volatilize at high temperatures, so it is difficult to spray. The volatilization of chromium oxide during spraying produces extremely fine dust particles that accumulate on the workpiece and become trapped inside the coating, reducing the cohesion and mechanical properties of the coating.

Dry ice blasting has been used in the field to improve the quality of chromium oxide and many other plasma sprayed coatings by keeping surfaces clean and helping with thermal management. During the spraying process, dry ice blasting was used to plasma spray the chromium oxide coating on the TUT through two different commercial dry ice blasters attached to the spraying robot. Several parameters were tested and temperature monitoring was implemented. Metallographic samples were prepared and analyzed by SEM. Hardness, adhesion, breathability and abrasion tests were also performed. Dry ice blasting was found to alter the temperature history of the substrate, and the coating significantly produced unexpected effects. Excessive cooling will reduce adhesion as shown in the graph, reducing cohesion and abrasion resistance, but some adverse effects can be better eliminated by adjusting spray parameters.

There are also large differences in the different jet patterns related to the particle size leaving the nozzle. Although the other ejector only ejects small dry ice dust that primarily cools the substrate, the larger particles with more kinetic energy ejected by the other ejector have a more positive effect on the cohesion of the coating compared to the non-dry ice sprayed samples influence. , thereby increasing the wear resistance. Plasma spraying is used to create ceramic coatings, especially for wear and corrosion applications. For example, alumina, titania and chromia are used as starting materials. Plasma sprayed chromium oxide coatings are widely used in rolls, seals and wear-resistant tire presses due to their good surface finish, high hardness and wear resistance.

However, chromium oxide is a challenging injection molding material due to its high melting temperature and low thermal conductivity. Chromium oxide also tends to evaporate at high temperatures, resulting in the formation of fine chromium oxide dust. The resulting chromium oxide dust is easily trapped between the coatings, weakening the cohesion and mechanical properties of the coatings.

Note: This article is reproduced from the online platform. If there is any infringement, please contact the website staff to delete it.