Application status of thermal spraying technology

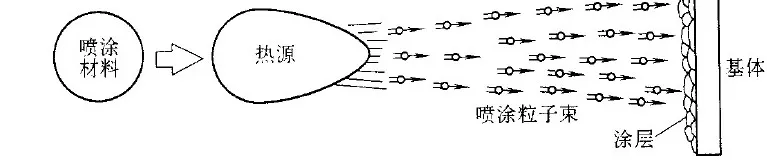

Thermal spraying technology is a modern processing technology with a wide range of technology, relatively simple and flexible processing technology, wide application range, and great economic benefits. The coating surface is wear-resistant, anti-corrosion, thermal insulation, heat resistance, electrical conductivity, insulation, and impact resistance. Corrosion, anti-oxidation, anti-friction, lubrication, anti-radiation and other functions. It can be used not only for repairing and surface strengthening of mechanical parts, but also for manufacturing.

Due to the wide selection of spraying materials, it is not limited by the alloying of the overall material, and it is easier to obtain super-hard alloys, various ceramic or cermet coatings and various functional coatings, and the coatings are relatively high compared to the overall high-grade materials. In other words, the amount of material used is less, which is undoubtedly much more economical than the overall improvement of the material. Therefore, precious materials can be used, the cost will not increase much, but the surface performance of the material can be greatly improved, and the service life of the parts repaired by thermal spraying can generally be Reach or even exceed the new product several times.

Coating materials involve almost all solid engineering materials, including metals, alloys, ceramics, cermets, plastics, metal plastics and their composite materials, and other inorganic non-metal materials. At present, it is widely used in aerospace and industrial gas turbines, boilers, petrochemical industries, printing, papermaking, general machinery, rotating targets and functional coatings, and steel industries. Thermal spray materials have greatly promoted the long-term development of these industries.

The future development trend and prospect of thermal spraying technology

From the perspective of future development trends, the research of thermal spray system engineering will receive more attention. At present, many countries have strengthened the research on thermal spraying system engineering, starting from failure analysis, and formulating thermal spraying implementation process plans through surface pretreatment, spraying equipment, spraying materials and spraying process optimization. In the development process, thermal spraying technology and other disciplines cross and penetrate each other to form a new surface treatment process. In the future, thermal spraying technology may be effective in the selection of spray materials, the bonding strength of the coating and the substrate, the research of basic theories, the research and development of new spray materials, the research and development of spraying processes and equipment, and the expansion of new application fields. Research and development.

Harbin Pei Ze Material Technology Co., Ltd. Products Introduction