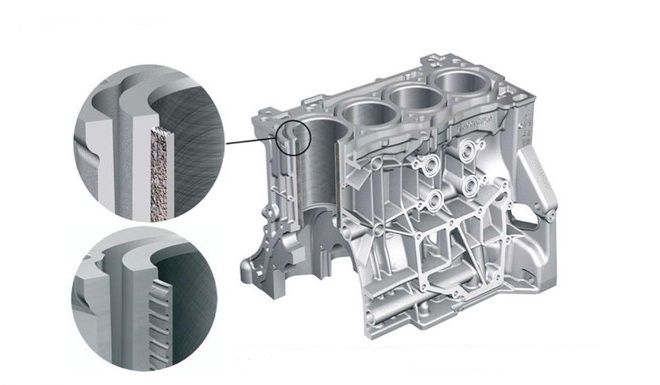

With the increasingly strict standards of automobile emissions and fuel consumption, the entire automobile industry is facing the challenge of energy conservation and environmental protection. In order to reduce fuel consumption and exhaust emissions, the traditional method is to reduce the weight of the car, so the aluminum alloy engine block replaces the cast iron cylinder body has become a development trend. In addition, the combustion efficiency of the engine can be significantly improved by reducing the friction inside the engine. A new automotive engine technology—linerless technology has attracted the attention of many automakers.

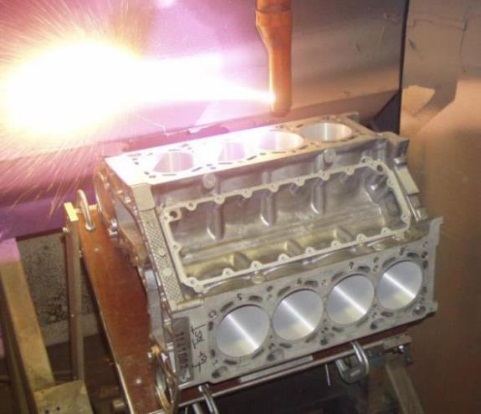

Automobile engine linerless technology refers to the introduction of thermal spraying technology in the production process of the engine block to spray a layer of wear-resistant low-carbon alloy coating on the surface of the pretreated aluminum engine cylinder bore, replacing the traditional cast iron cylinder liner. The cylinder block is still a one-piece cylinder block. The process of the cylinder without liner mainly includes: casting, roughing, roughening the surface of the cylinder bore, preheating, spraying, finishing, and honing. The following is a brief description of one of the key processes of the linerless technology, the surface roughening method of the cylinder bore:

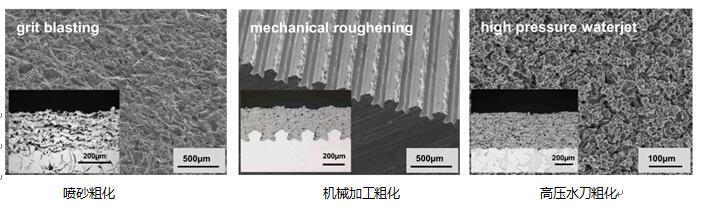

The purpose of surface roughening is to increase the surface area, form a surface structure that enables mechanical bonding between the coating and the substrate surface, increase the mechanical occlusal force between the coating and the substrate, make the surface more active, and then improve the coating and the substrate. bond strength of the material. There are many ways of surface roughening, such as sandblasting, machining roughening, high-pressure water jet roughening, etc. Among them, sandblasting is the most commonly used roughening treatment method, which is suitable for roughening treatment of all metal surfaces. After sandblasting, a clean, rough and highly reactive surface can be obtained for metal materials, and oil-free high-pressure dry air needs to be used to clean the roughened surface before spraying. Machining roughening is to machine the surface of the aluminum cylinder into a certain profile, using a single-axis machining center and using a Mapa knife, which has the characteristics of high efficiency, low machining cost and one-time machining. When roughening the cast iron cylinder block, the wear of the tool is large and the economical applicability is poor. High-pressure water jet roughening is only suitable for aluminum cylinders, not for cast iron cylinders. It does not use abrasives, and directly uses liquid jets to wash the surface of the substrate. After roughening, it only needs to be dried, but the surface roughness value is relatively low.

As a key process in the linerless technology, surface roughening directly affects the bonding strength and coating performance of the coating. Therefore, it is necessary to pay attention to the surface roughening process during the processing of the linerless cylinder, and select an appropriate roughening method. , to achieve the best activation surface and production efficiency.

This article is reproduced from the online platform. If there is any infringement, please contact the website staff to delete it, thank you