| Type of powder material |

| Cr₃C₂-NiCr Nickel-chromium carbide composite powder 75/25 Reunion sintering |

| brand(PZ) |

| PZ-701 |

| specifications(um) |

| 38/10 45/15 53/20 |

| Performance and application |

|

HVOF, HVAF, APS medium grain chromium carbide The maximum operating temperature 870 ℃ excellent abrasion resistance, particle corrosion resistance and high temperature gas corrosion resistance for stem, turbine components, fuel rod mandrel, pump housing, hydraulic valves, thermal forming, etc. |

| W | Balance |

| Cr₂0₃ | 38.5-43.5 |

| C | 7.7-8.5 |

| Co | 2.9-4.1 |

| Ni | 10.0-13.0 |

| Fe₂0₃ | < 0.5 |

| Nominal Range um | D95um | D5um |

| -53+20 | 53 | 20 |

| -38+10 | 38 | 10 |

| -45+15 | 45 | 15 |

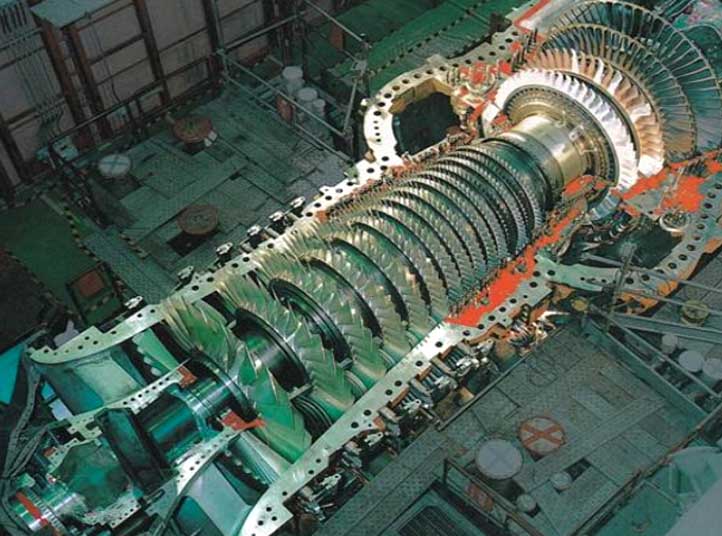

| Turbine blade | The steam turbine |

| Part function:Boost engine | Part function:Boost engine |

| Matrix material:Cast aluminum silicon alloy | Matrix material: Cast aluminum silicon alloy |

| Function of the coating:Increase engine efficiency | Function of the coating:Increase engine efficiency |

Process technology: Atmospheric plasma spraying or HVOF |

Process technology: Atmospheric plasma spraying or HVOF |