Coatings that have been sprayed sometimes cannot be used directly and must undergo a series of post-treatments. The coating used for corrosion protection must be sealed to prevent the corrosive medium from penetrating the pores of the coating to the substrate to cause corrosion of the substrate. There are many materials used as seal sealers, but they should be considered according to various factors such as the working medium, environment, temperature and cost of the workpiece.

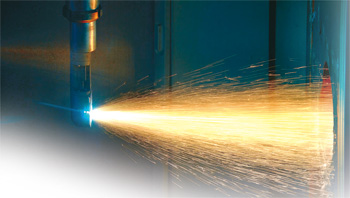

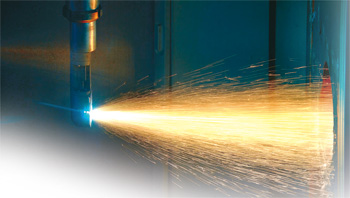

For workpieces subjected to high stress loads or impact wear, in order to improve the bonding strength of the coating, the sprayed layer should be remelted (such as flame remelting, induction remelting, laser remelting, and hot isostatic pressing) to make the porous The coating that is only mechanically bonded to the substrate becomes a dense coating that is metallurgically bonded to the substrate with dimensional accuracy requirements, and the coating is machined.

Because the spray coating has different characteristics from the general metal and ceramic materials, such as the micropores in the coating, it is not conducive to heat dissipation; the strength of the coating itself is low and cannot withstand a large cutting force; there are many hard coatings in the coating. The particle point, the wear of the tool is very fast, etc., thus forming a difficult coating characteristic of the spray coating different from the general material. Therefore, it is necessary to select reasonable processing methods and corresponding process parameters to ensure the smooth operation of the spray coating and to ensure the required dimensional accuracy.